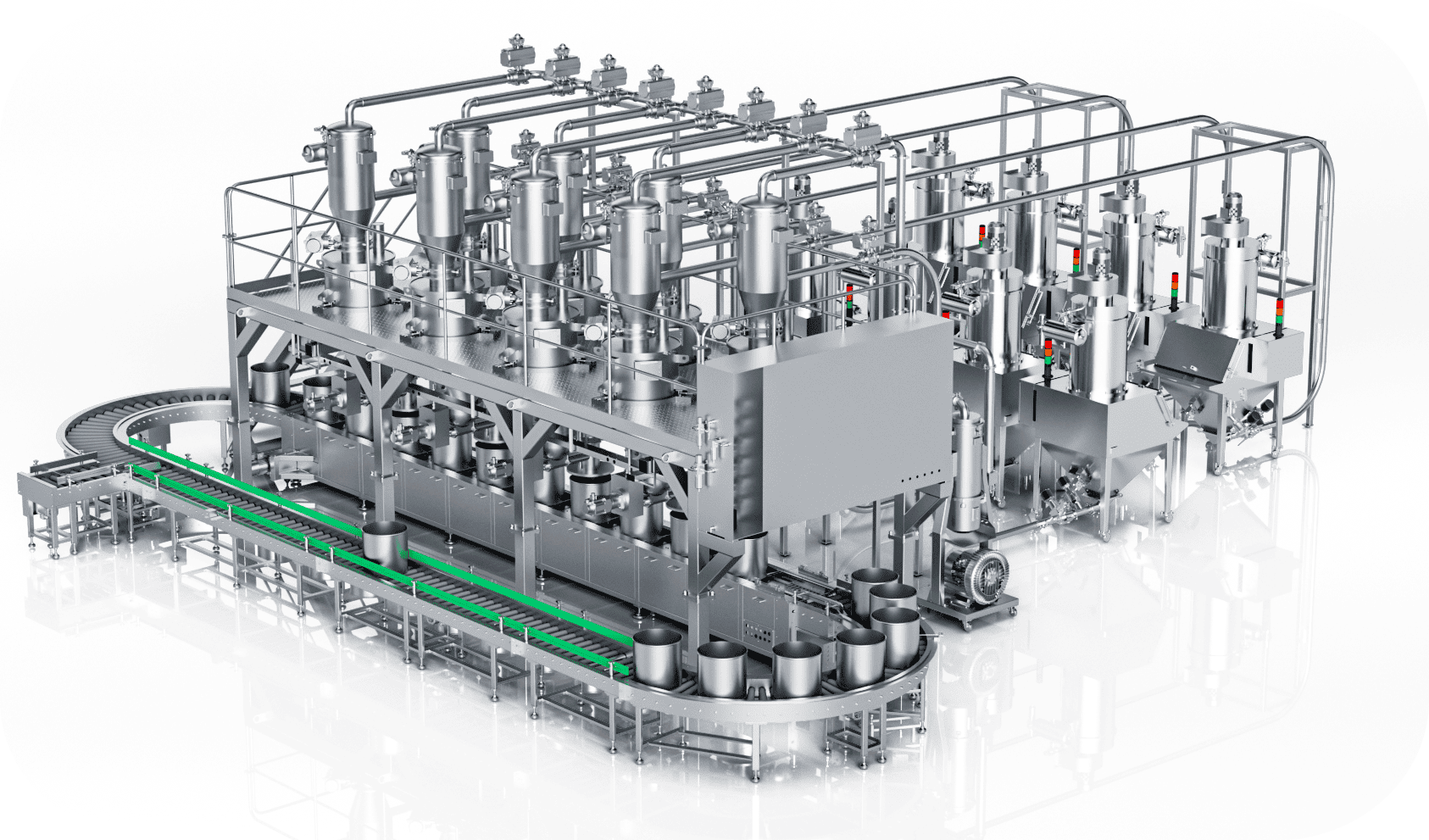

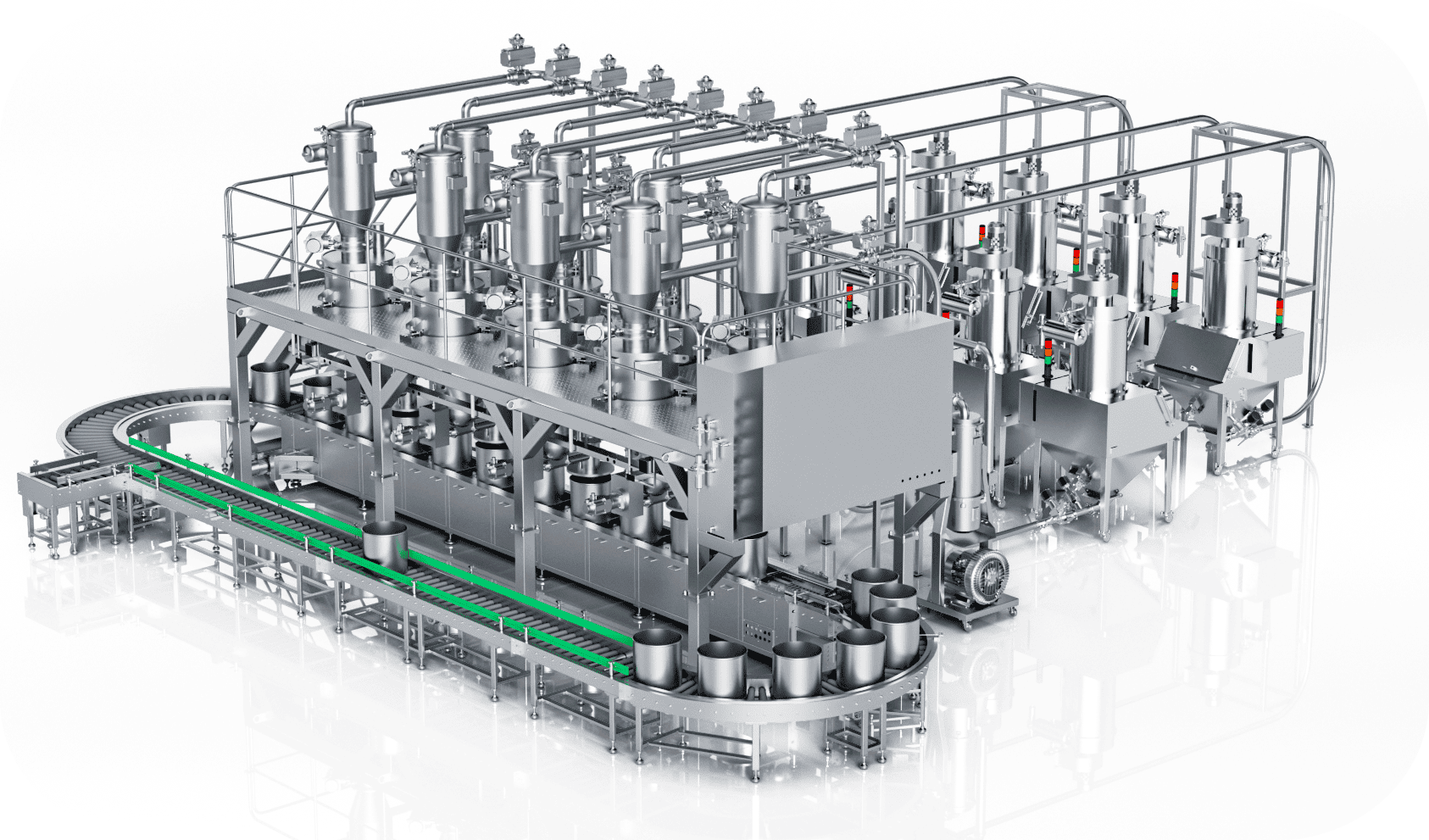

Intelligent micro batch dosing system: The precise choice for the fast food industry

In the fast food industry, the intelligent micro batch dosing system has been widely applied in various production scenarios.For instance, in the production process of instant foods such as instant noodles, rice noodle soup with snails, and spicy and sour noodles, the system can precisely control the amount and timing of raw materials like flour, seasonings, and vegetable packets, ensuring the taste and quality of the products.Meanwhile, the system can also monitor the quality and usage of raw materials in real time, promptly detect and handle abnormal situations, and ensure the safety and stability of the products.The intelligent micro-ingredient system, with its characteristics of high efficiency, precision and intelligence, is changing the production mode of variable-speed food.

The system brings significant advantages to the food industry:●High production efficiency

Automated operation: Through automated control, the need for manual operation is reduced, significantly improving production efficiency.Flexible operation: The batching system can quickly adjust the formula according to market demand to ensure the continuous operation of the production line.

●High product quality

Precise measurement: Each workstation can perform unit static re-weighing, and the final static re-weighing is carried out at the end to achieve high-precision weighing and batching.

Eliminating human errors: Equipped with a QR code management function, operators do not need to perform frequent manual addition operations, reducing the errors and waste caused by manual addition and ensuring the accuracy of raw material supply.

●Low operating cost

Low raw material waste: Precise ingredient control reduces raw material waste and lowers production costs.Automated cleaning: Reduce manual maintenance costs and increase the utilization rate of equipment.

●Improve food safety

Dust-free operation: The batching system is equipped with a central dust removal system to ensure the entire system operates dust-free, enhancing food safety.Data traceability: The system can record detailed data of each ingredient preparation, facilitating traceability and quality control.

Lingood intelligent micro batch dosing system helps customers in the food processing industry achieve efficient and high-quality production. We have efficient and stable equipment, a professional technical team, and a prompt after-sales service response. We are committed to solving the production problems in the food industry. Let's create more delicious and healthy food together and meet consumers' pursuit of a high-quality life.

Company Profile

Company Profile

Development History

Development History

Manufacturing Facilities

Manufacturing Facilities

Credit

Credit

Partners

Partners

Product Center

Product Center

System Center

System Center

Service Innovation

Service Innovation

Technological innovations

Technological innovations

Company News

Company News

Exhibition Info

Exhibition Info

Lingood Technology

Lingood Technology

Customer Cases

Customer Cases

Multimedia Downloads

Multimedia Downloads

Global Network

Global Network

Service Contacts

Service Contacts

Join Us

Join Us

Investor Contact

Investor Contact

General Information

General Information

Company Announcement

Company Announcement